The Best Battings For Your First Quilts

Batting is the inner layer between the top of the quilt and the back of the quilt. It is this stuffing that makes a quilt a quilt, and not a blanket. There is a dizzying array of battings available to the quilter these days! I will break it down for you and suggest a good quilt batt for the beginner.

Thirty-four years ago, when I began to make quilts, there were few choices from few companies: traditional cotton batting (low-loft) and polyester batting in fluffy and low-loft. I hand quilted at the time, so a low-loft polyester batting was my best choice because it was easy to hand quilt.

I machine quilt now, so I can quilt easily through cotton batting, so a traditional or low-loft cotton batting is what I choose for most of my quilts. However, most of my quilts are artwork for the wall with lots of embellishing and quilting, so I want a very flat finished look. I get that with cotton.

For bed, baby and lap quilts, many people choose to use polyester batting for several reasons:

1. It is relatively inexpensive.

2. It washes beautifully and doesn’t shrink.

3. It gives a lovely loft to the quilt stitching, creating that great quilted texture.

My suggestion is to use good quality low-loft polyester batting for your first quilts.

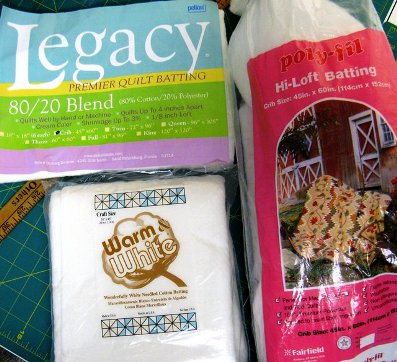

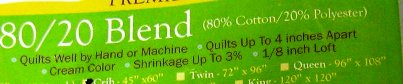

That being said, the internet has many sites about quilt battings. For instance, the companies that make them have charts that explain the fiber content and intended use for each batt. It is hard to stay current with all the innovations made by the batting companies….they are improving and adding to the variety of products all the time. A few of the companies that make good battings are Legacy (by Pellon), Mountain Mist, Hobb’s, Fairfield, Quilter’s Dream, and Warm’n Natural.

The packaging will also give you information about the fiber content, instructions for use and other important information.

Competition quilters (those that enter contests to win) use specialty battings for their unique qualities. Three notable examples are:

1. Wool batting- it is very springy, so when you have a very closely quilted design, the batting still fluffs up in the un-quilted spaces.

2. Silk batting- you can get a lovely quilted texture even when quilting very close. It keeps the quilt soft, drapey and lightweight.

3. Bamboo batting- environmentally friendly as it is a renewable source. This batting is lovely to the touch and quilts like butter by hand or machine.

Some fabric stores have batting on a roll with no brand on it. This stuff may be for upholstery or it may be a low quality batting. Check to see if there are holes in it, rough texture or globs of resin. Don’t use it if you spot these things.

Some fabrics have good quality batting on rolls or boards….these will have a brand on the ticket and this is a great way to get batting at a good price.

The thing to do is to go to your local fabric store or quilt shop and see what is available. I like to pick up samples of different battings when I go to the quilt shows, too. When you have the chance to pick up samples of different battings, use them to make samples for yourself so that you can see the different qualities yourself.

You can get battings in white, natural and black. The white is, of course, good for a pure white quilt and the black for a black or very dark colored quilt.

Keep in mind that when you hear about a great batting from somebody, they are talking from the experience of using it in the type of quilts they make, in other words, consider the source. The fiber content and the way different battings are made really do make a difference in the way they perform and finish when made into a quilt.

Click HERE to see more articles by Terry.